Precision Push to Connect Fittings

Direct manufacturer with certified quality

Push to Connect Fitting Factory in China

Push to Connect Fittings Manufacturer

As a leading push to connect fittings manufacturer and supplier, AirFluid delivers precision-engineered fluid system components that meet international quality standards for global industrial applications.

Application of Push to Connect Fittings

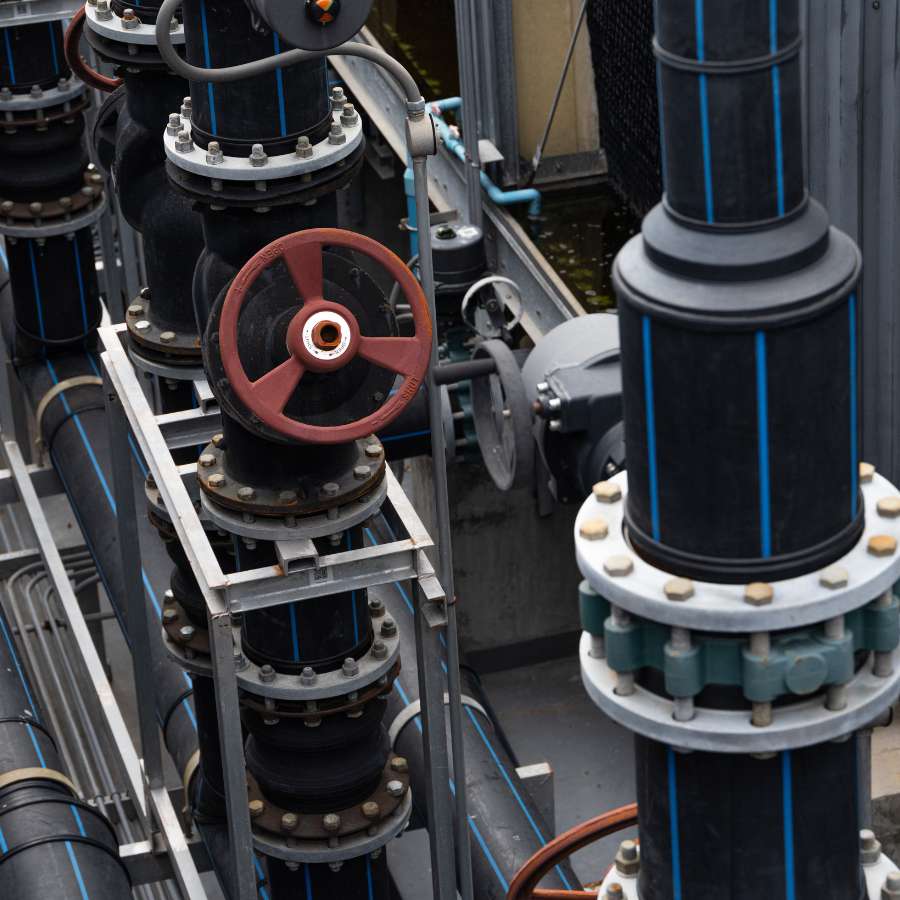

Push to connect fittings are widely used in pneumatic, air, water, and fluid transfer systems due to their fast installation, reliable sealing performance, and tool-free operation. These fittings are suitable for applications requiring frequent assembly and disassembly while maintaining secure, leak-resistant connections.

Available in materials such as brass, stainless steel, and copper, push to connect fittings can be applied in industrial automation, construction equipment, material handling systems, agricultural machinery, HVAC, and plumbing applications. Their versatility and ease of use help improve installation efficiency and system reliability across various industries.

AirFluid push-to-connect air and tube fittings are extensively used in automated equipment and pneumatic control systems, improving assembly efficiency and simplifying maintenance.

In construction applications, AirFluid push-to-connect fittings support air tools, compressed air systems, and temporary fluid lines on job sites.

AirFluid fittings are widely used in conveyors, forklifts, lifting devices, and pneumatic actuators for stable air supply.

In agricultural machinery and irrigation systems, AirFluid push-to-connect fittings provide reliable air and fluid connections.

Copper and brass push-to-connect fittings are commonly used in HVAC and plumbing systems for fast installation.

AirFluid push-to-connect fittings are used in air brake, suspension, and fluid systems for reliable performance.

Why Choose AirFluid as Your Push to Connect Fittings Manufacturer?

- Specialized Push to Connect Manufacturing – We maintain dedicated production lines for push to connect fittings, ensuring consistent quality and rapid delivery for bulk orders.

- Global Material Certification – All raw materials for our push fit fittings are sourced from certified suppliers, with full traceability and material test certificates available.

- Custom Engineering Support – Our technical team provides design assistance for custom push to connect solutions, including CAD modeling and prototype development.

- Comprehensive Quality Assurance – Every batch of push connect fittings undergoes pressure testing, leak testing, and dimensional verification before shipment.

- Export Packaging Expertise – We provide export-ready packaging with proper labeling and documentation for international shipments.

Partner with a Reliable Push to Connect Fittings Supplier

As an experienced push to connect fittings supplier, we understand the critical requirements of fluid system applications. Our manufacturing facility is equipped with advanced CNC machines and automated assembly lines to ensure consistent quality across all our push fit products.

We serve clients across multiple industries including pneumatic systems, instrumentation, water treatment, and industrial automation. Our technical support team is available to assist with product selection and application engineering.

With years of experience as a professional push to connect fittings manufacturer, we have built a reputation for reliability and quality in the international market. Our commitment to continuous improvement ensures that we remain at the forefront of push connect fitting technology.